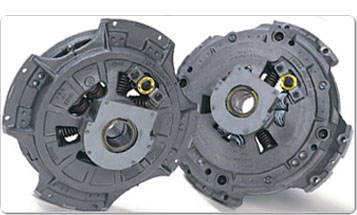

All clutches are remanufactured to Eaton/Spicer original factory specs and components are supplied by OE approved suppliers. Due to D&W's attention to detail and because they follow all the manufacturers' specifications to the letter we feel D&W offers the finest remanufactured clutch in the U.S. They are so confident about their clutches that they have a one year or unlimited mileage warranty. Matching Eatons current warranty. We stock popular 14 and 15-1/2 clutches. Check out the clutch application guide for proper clutch selection

The standard procedures followed at D&W for remanufacturing an Eaton cast iron angle spring clutch involves several stages and inspections. A core received at their facility is disassembled completely and the components may be washed, baked, shot blasted, wear points inspected with micrometers, welded, and milled back to original specifications. Assembly consists of approximately 50% new internal components, EPII Lithoplex high temperature grease, new pressure and retractor springs, new press-fit coaxial chrome-vanadium disc springs, and new center plates. All matched units have clutch assemblies adjusted on a simulated flywheel with the discs and center plate that are in the box. Incorrect center plate or disc thickness (due to machining used plates), warped or bent discs, and therefore improper clutch adjustment are frequent problems for mass production clutch rebuilders who adjust clutch assemblies to "dummy" discs. Due to their use of new center plates, inspections, and true matched unit adjusting procedures, we virtually eliminate these occurrences.

Home - Staff - Line Sheet - Services - Trailers - Specials - Tech Notes